Introduction: Technical Features & Design Standards of VAV – A Beginner’s Guide for Young Engineers

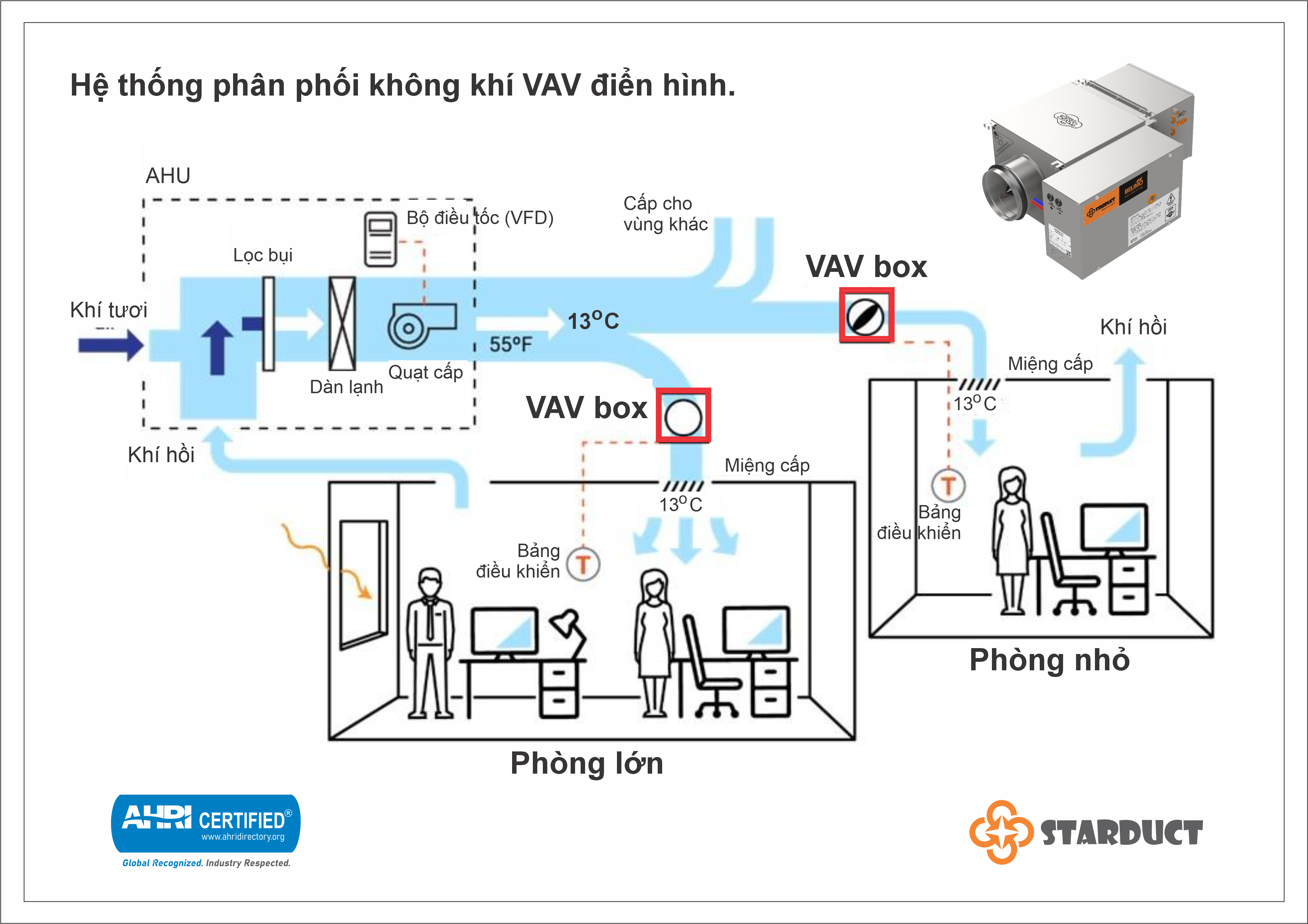

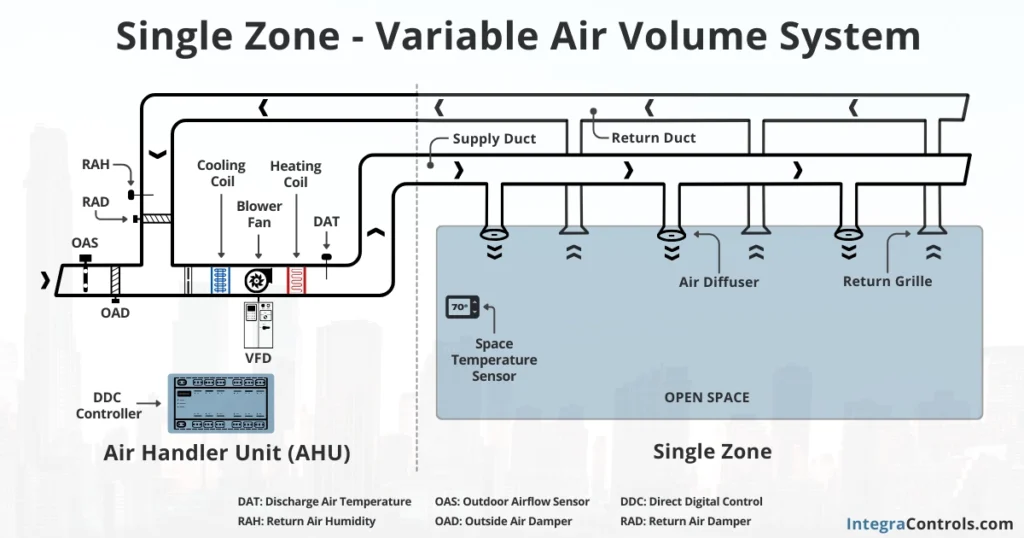

The VAV (Variable Air Volume) Box system is a modern air conditioning solution that adjusts supply airflow based on the actual load of each zone. To design an effective and sustainable VAV system, engineers must understand the following key technical features and design standards.

Basic Technical Specifications of VAV Boxes

- Airflow Range: Must ensure both Qmin (minimum fresh air) and Qmax (suitable for zone design load).

- Small VAV: 30–300 L/s

- Medium VAV: 300–1,000 L/s

- Large VAV: >1,000 L/s

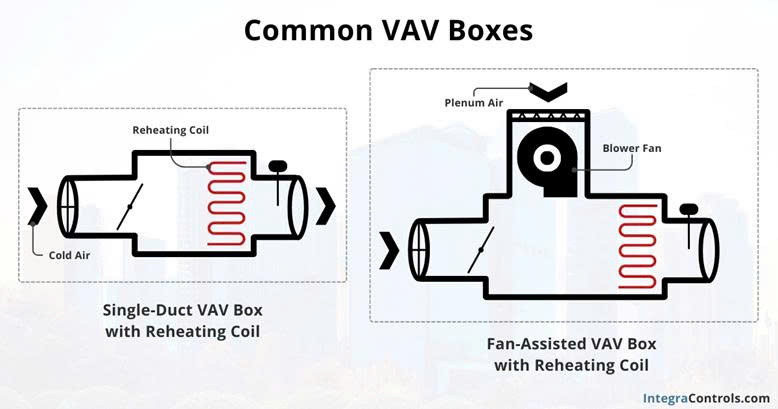

- Noise Level: Should meet NC25–35 at design airflow (refer to ASHRAE Applications Handbook – Sound and Vibration Control).

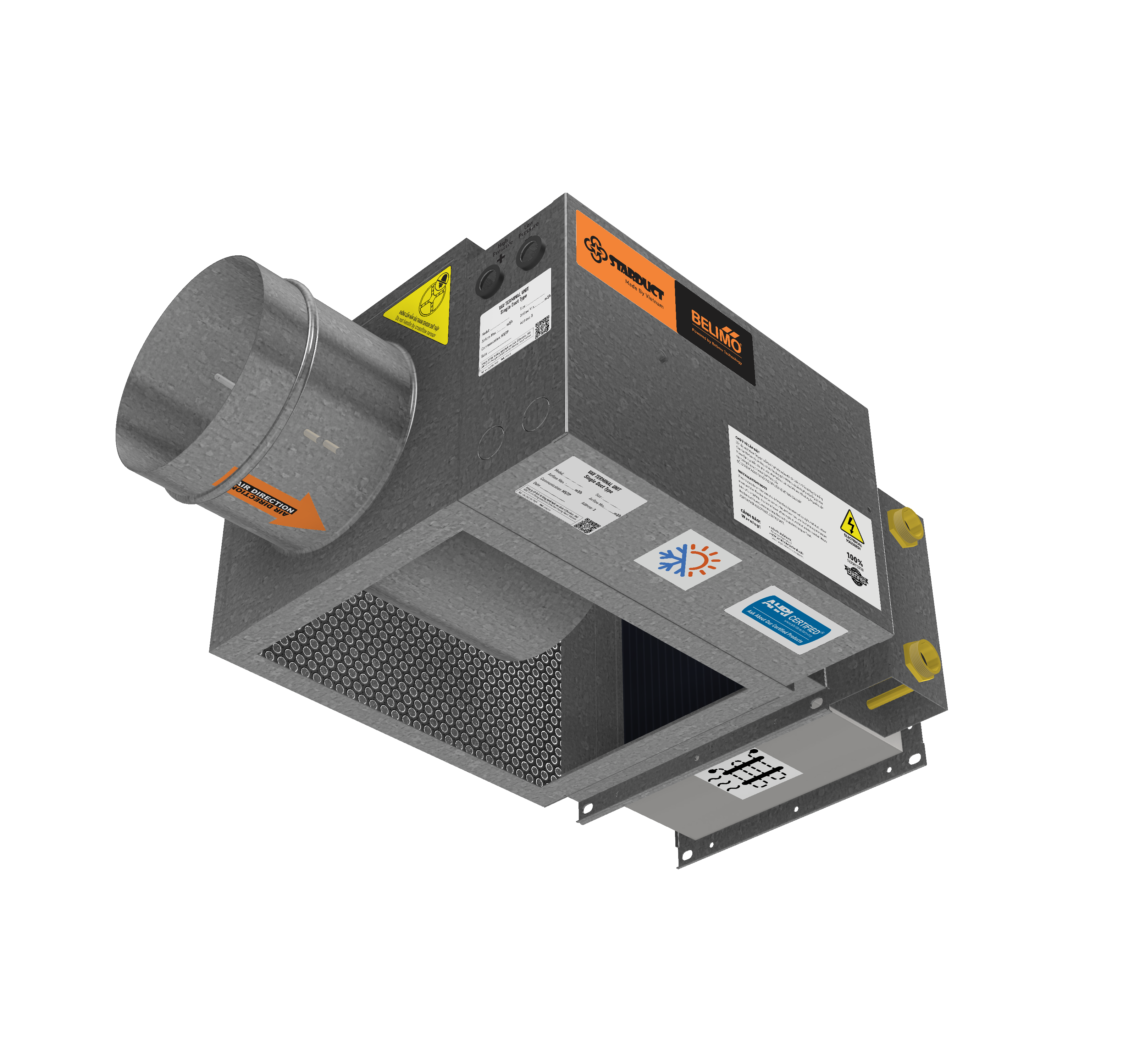

- Airflow Measurement Accuracy: Per AHRI 880, minimum ±5% accuracy at ΔP ≥ 50 Pa.

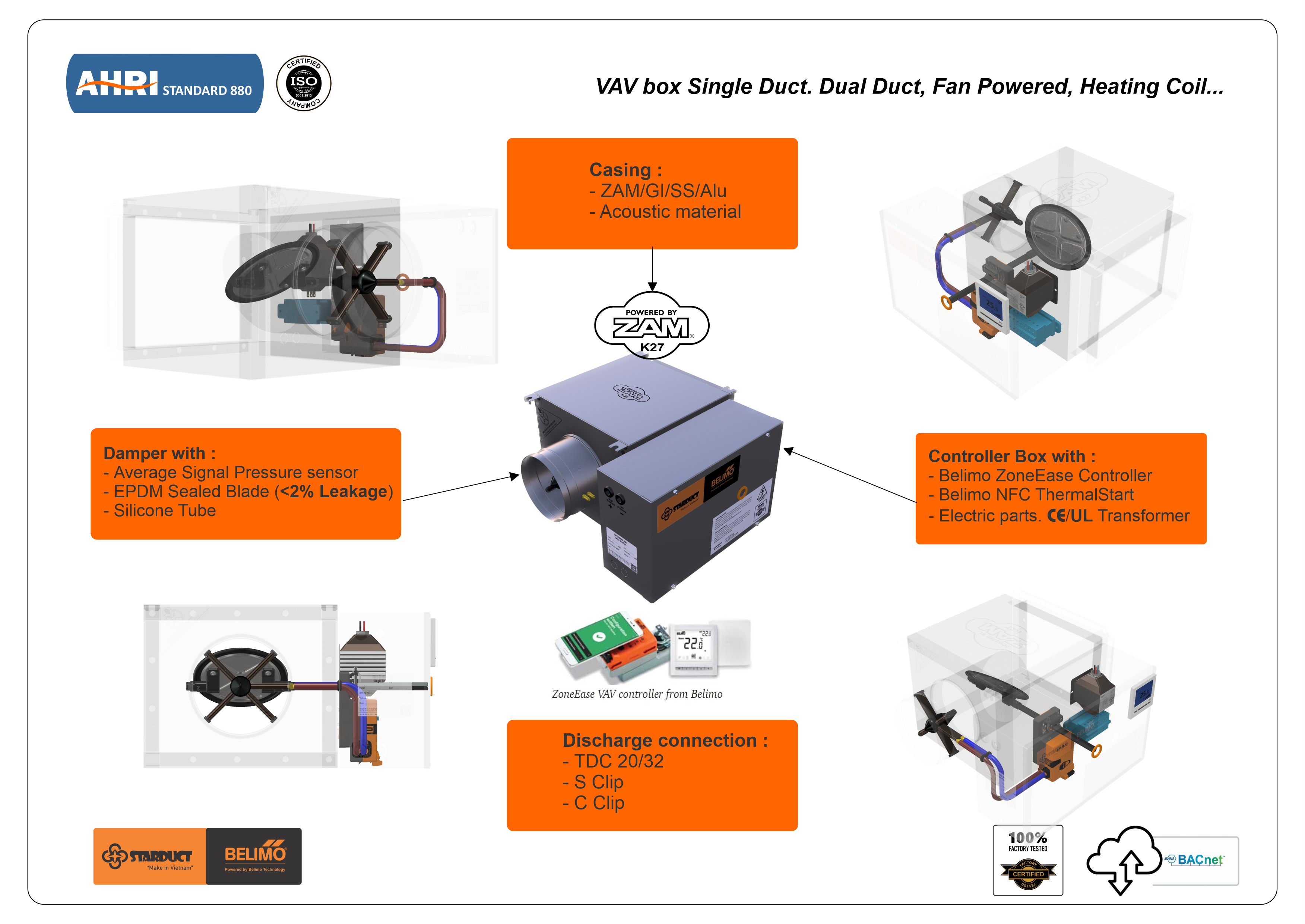

- VAV Types:

- Single duct

- Fan-powered

- VAV with integrated heater (electric/hot water coil)

Design Standards to Follow

- AHRI 880 – Performance Rating of VAV Terminals Defines measurement methods for noise, airflow accuracy, and air leakage. ✅ Tip: Choose AHRI 880-certified devices to ensure reliable performance.

- ASHRAE 62.1 – Ventilation for Acceptable Indoor Air Quality Specifies minimum fresh air requirements for each space. ✅ Tip: Never allow VAV to drop below minimum fresh air under any load.

- ASHRAE 90.1 – Energy Standard for Buildings (Except Low-Rise Residential) Promotes energy-efficient design and prevents oversizing. ✅ Tip: Use EC motors and actuators to save energy and reduce central fan load.

- SMACNA – HVAC Systems Duct Design Manual Guides VAV and duct layout to reduce turbulence and noise. ✅ Tip: Maintain straight duct length before VAV at 3–5 times duct diameter.

- AMCA 300 / ISO 3741: Noise testing standards.

- EN 1751 – Air Tightness of Components: Evaluates leakage in dampers and valves.

Recommended References for Deeper Study

- AHRI 880 –

- ASHRAE 62.1 / 90.1 / Applications Handbook –

- SMACNA Duct Design Manual –

- AMCA Standards –

Contact NSCA for translated documents in Vietnamese/English.

Practical Notes for Beginners

- Always ensure minimum fresh air at VAV minimum setting (ASHRAE 62.1).

- Avoid oversizing VAV—select the correct airflow range (ASHRAE 90.1).

- Choose AHRI 880-certified equipment for reliable operation.

- Optimize duct layout before VAV (SMACNA) for noise reduction and accurate measurement.

Conclusion

Understanding the standards and designing correctly from the beginning is the key for young engineers to confidently build VAV systems that meet comfort, energy efficiency, and sustainability goals. Start with the original documents above, and don’t hesitate to consult experienced colleagues to sharpen your design skills!

Want to dive deeper? Connect with us for more advanced materials and real-world case studies on internationally compliant VAV design.

#VAVBox #HVAC #AHRI880 #ASHRAE #SMACNA #AMCA #ComfortEngineering #GreenBuilding #Starduct #NSCA

Bình luận (0)