Comparison of VAV and VRF Systems: Which HVAC Solution Fits Your Building Best?

In modern commercial and institutional building design, HVAC systems play a crucial role in ensuring comfort, energy efficiency, and cost-effectiveness. Among the most widely adopted systems are Variable Air Volume (VAV) and Variable Refrigerant Flow (VRF) solutions—each offering distinct advantages depending on project needs. This article explores how these systems work, where they excel, and how you can determine the best fit—or combination—for your building.

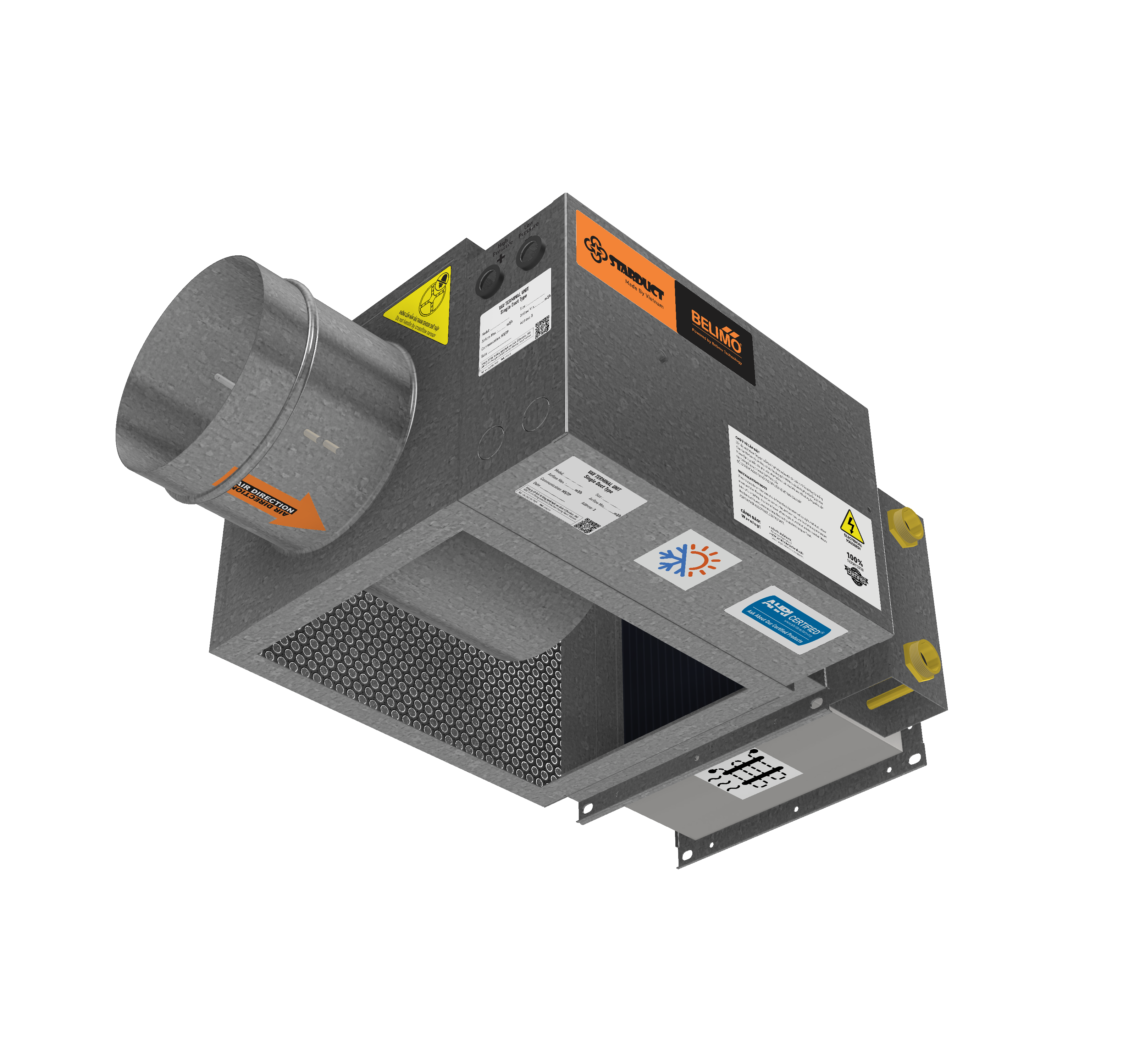

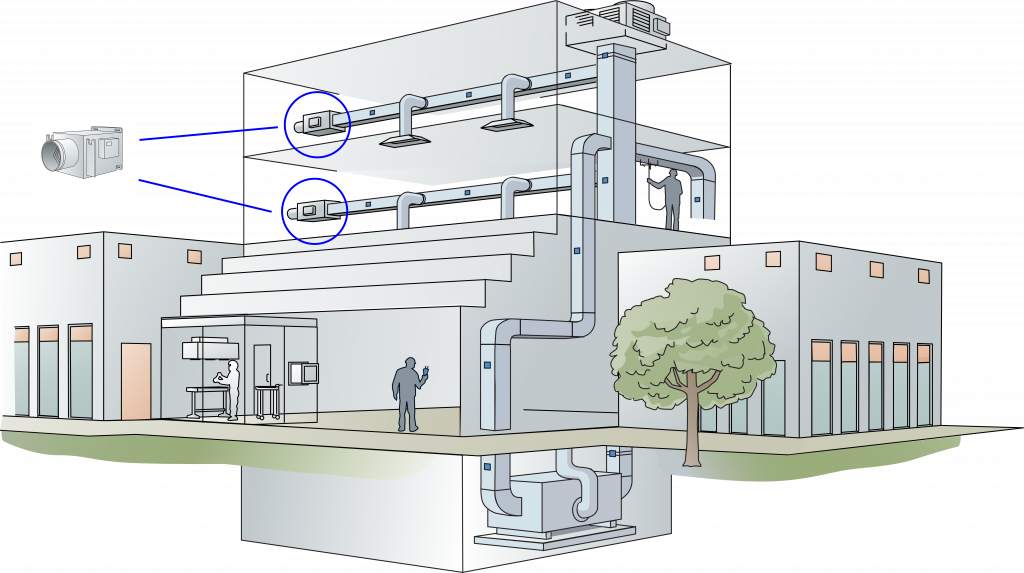

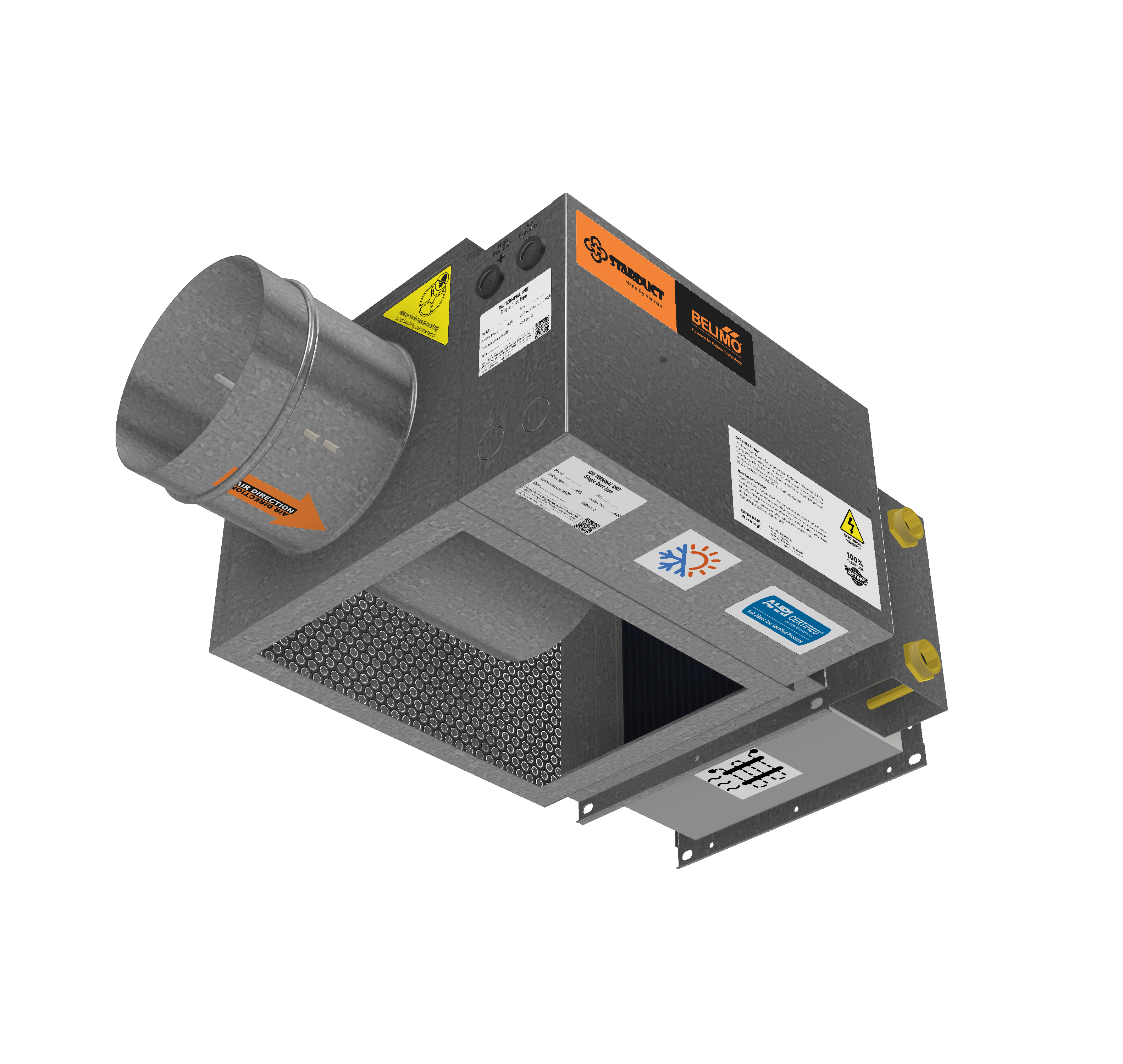

Nhà ga T3 sân bay Tân Sơn Nhất - HCMC Việt Nam - Nơi lắp đặt 745 bộ VAV Single Duct hiệu Starduct-Belimo. Hoàn thành tháng 4 năm 2025.

What Are VAV and VRF Systems?

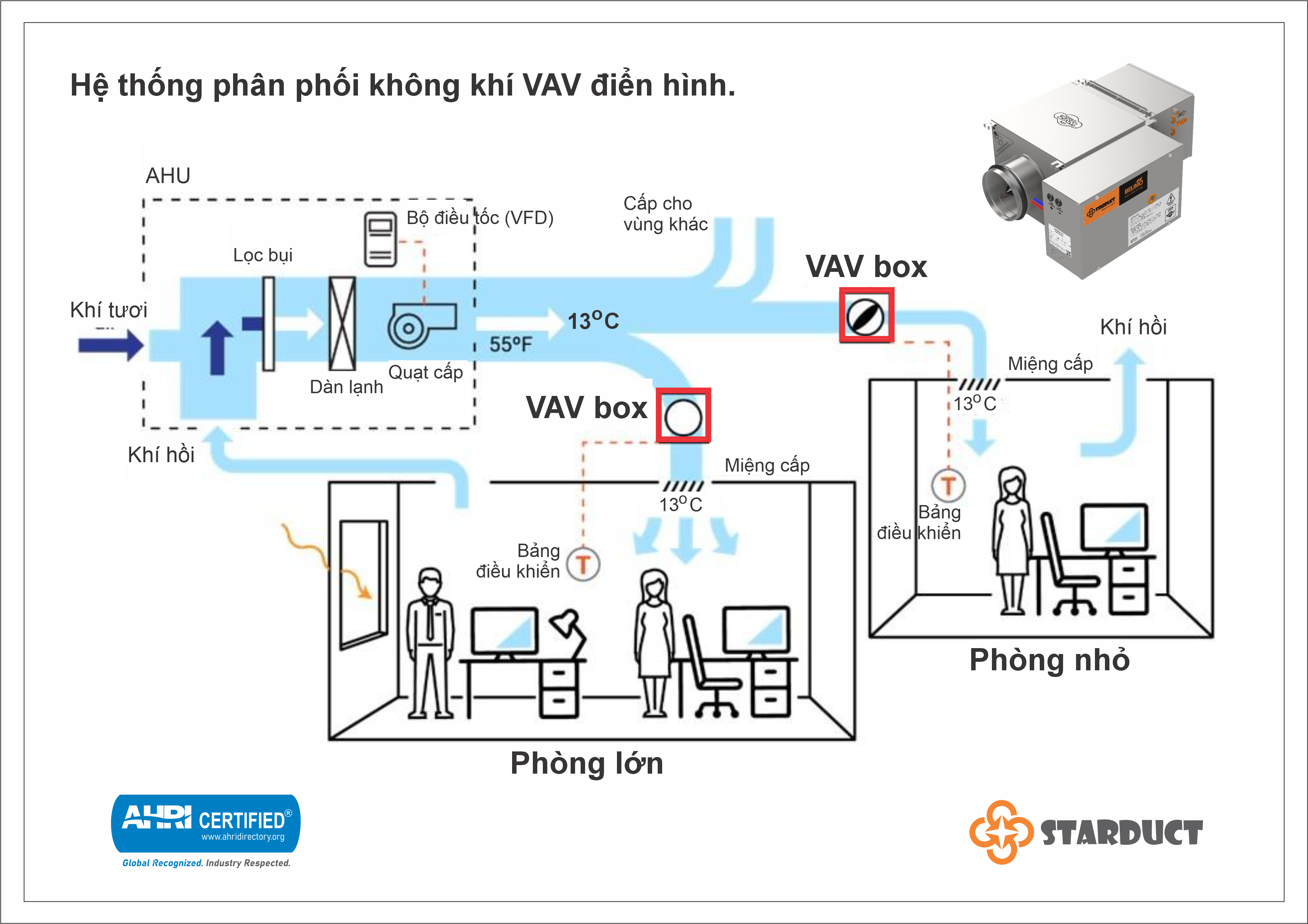

VAV (Variable Air Volume):

- Central AHU (Air Handling Unit) conditions air to a fixed temperature.

- Air is distributed via ductwork to different zones.

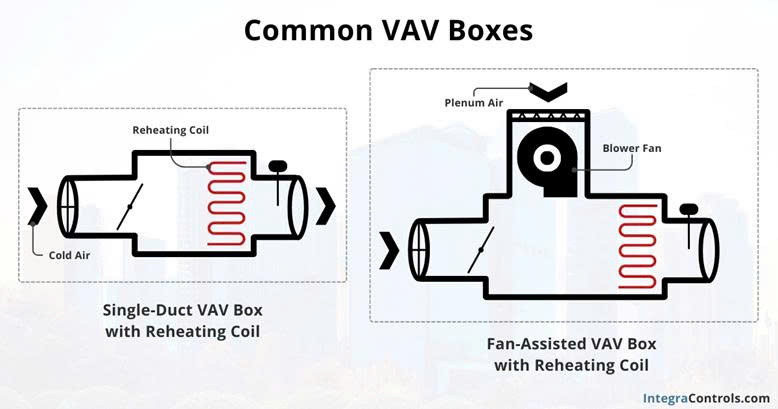

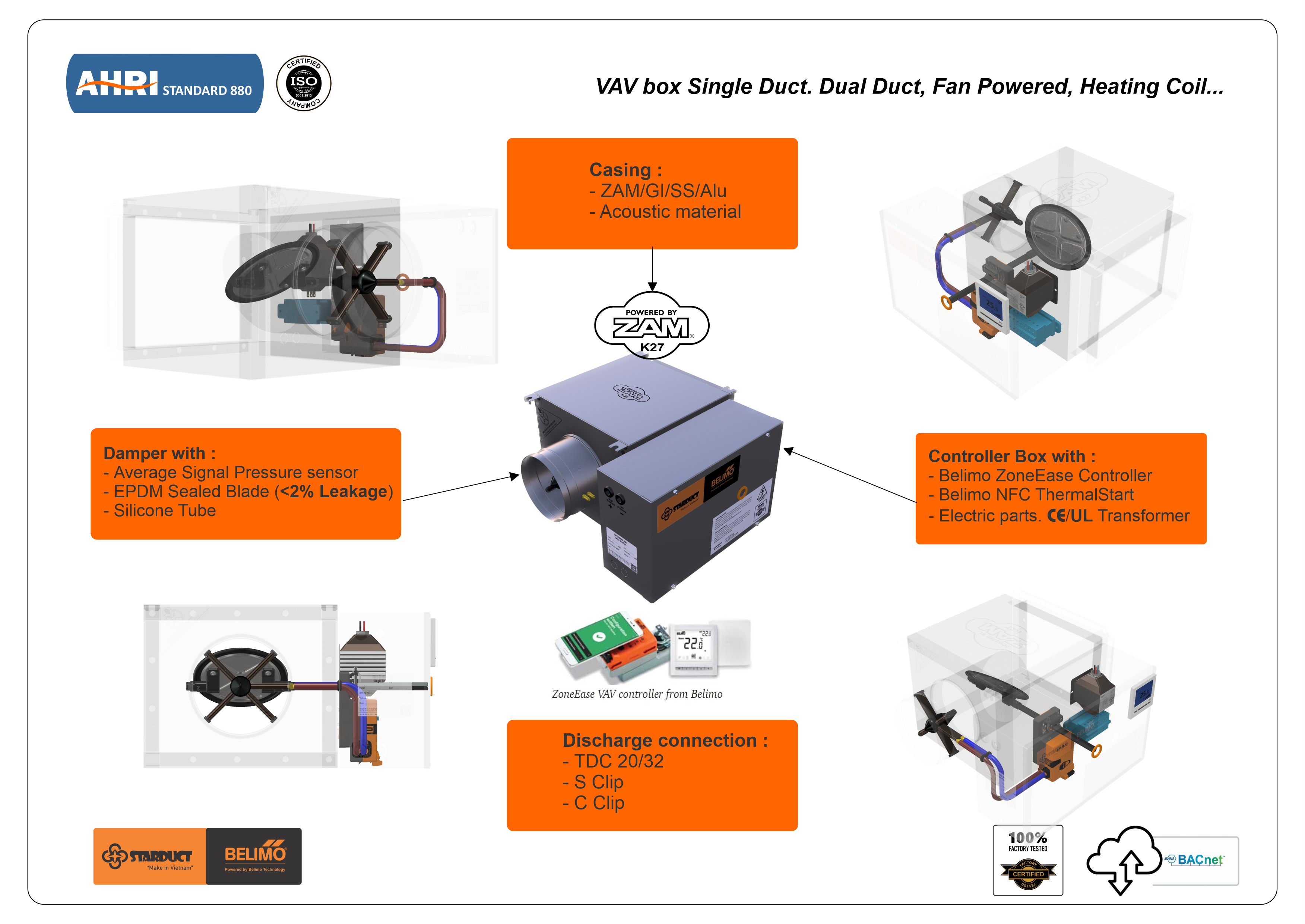

- Each zone has a VAV box with a damper that adjusts airflow to meet its temperature setpoint.

- Entire supply air remains at constant temperature; thermal comfort is achieved by modulating airflow.

- Often includes reheat coils in perimeter zones for additional heating needs.

- Requires significant space for ductwork, making it best suited for buildings with generous ceiling plenum space.

VRF/VRV (Variable Refrigerant Flow/Volume):

- Uses refrigerant as the direct heat transfer medium (no chilled water or large ductwork).

- An outdoor unit connects to multiple indoor units via refrigerant piping.

- Each indoor unit operates independently with an electronic expansion valve.

- Heat recovery VRF systems allow simultaneous heating and cooling in different zones.

- Highly flexible for retrofits and space-constrained projects.

Pros and Cons at a Glance

| Feature | VAV System | VRF/VRV System |

|---|---|---|

| Initial Cost | Lower for large buildings | Higher due to advanced technology |

| Energy Efficiency | Moderate, centralized fan runs continuously | Excellent, part-load performance is optimized |

| Zoning Flexibility | Good | Superior (individual control per unit) |

| Maintenance | Simpler, well-known technology | Requires specialized service |

| Space Requirements | Needs duct space | Minimal ducting, uses slim refrigerant piping |

| Retrofit Compatibility | Challenging in tight spaces | Ideal for renovations |

| Simultaneous Heat/Cool | Needs reheat energy | Supported in heat recovery systems |

Energy Performance & Real-World Impact

Real-world studies consistently show VRF systems offer notable energy savings:

- U.S. General Services Administration reports VRF can reduce HVAC energy use by over 34% versus conventional systems.

- In China, VRF-equipped office buildings used up to 70% less cooling energy than comparable VAV installations.

- VRF’s ability to serve part-time, part-space demand means only the needed areas are cooled—unlike some VAV systems that run full-time.

Yet, VRF's efficiency advantage depends heavily on operation. Improper control strategies or uniform temperature settings may reduce its benefit. Conversely, in full-load, always-on environments like factories or data centers, traditional VAV may be more cost-effective.

Making the Right Decision: Life-Cycle Cost Matters

Choosing between VAV and VRF isn’t just about equipment price. Engineers recommend conducting a Life-Cycle Cost (LCC) Analysis, considering:

- Capital cost

- Annual energy savings

- Maintenance complexity

- Building size, layout, and usage patterns

In general:

- VAV is cost-effective for large buildings with centralized mechanical space and predictable occupancy.

- VRF excels in projects with spatial constraints, varying usage, and an emphasis on long-term energy savings.

Hybrid Solutions for Optimal Results

Many developers are now adopting hybrid designs—using VRF for small or renovated areas, and chiller/VAV systems for large zones. This strategy combines the best of both worlds: VRF’s energy efficiency and flexibility, with VAV’s cost advantages for core spaces.

By Star Asia R&D Dept.

#HVAC hashtag#Construction hashtag#EngineeringExcellence hashtag#Starduct hashtag#MadeInVietnam hashtag#ProjectShowcase hashtag#QualityMatters

Bình luận (0)