What is a Multi-Zone Variable Air Volume (VAV) System?

Source:

Tổng hợp và biên dịch bởi phòng nghiên cứu và phát triển NSCA

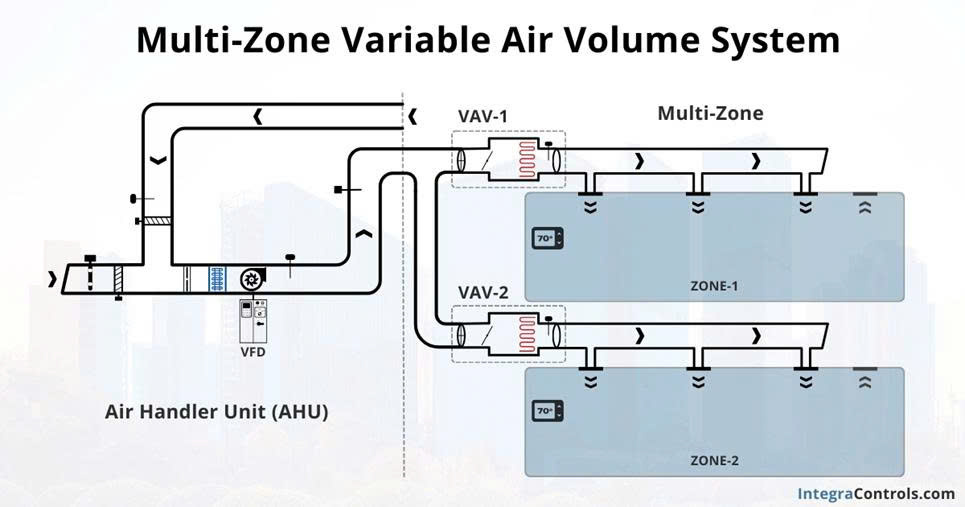

A multi-zone variable air volume (VAV) system is a type of heating, ventilating, and air conditioning (HVAC) system designed to ensure space comfort in large facilities and commercial buildings. It achieves this by distributing air from a central air conditioning (AC) unit to multiple rooms. The system uses dedicated terminal units for specific zones, adjusting the supply airflow and discharge air temperature to meet the varying space loads and provide optimal comfort.

Variable Air Volume (VAV) System Applications

There are two main types of variable air volume applications:

Single Zone VAV System: Suitable for open-space HVAC applications such as restaurants, auditoriums, and open office spaces.

Multi-Zone VAV System: Ideal for multi-room comfort HVAC applications in office buildings, hospitals, medical centers, schools, colleges, universities, and various other building environments where different zones experience significant space load variations throughout the day.

Multi-zone variable air volume systems represent the evolution of their constant air volume (CAV) counterparts, such as terminal reheat and mixed air systems. They also represent a significant improvement in efficiency and performance when compared to variable volume and temperature (VVT) systems.

Multi-zone VAV systems are highly precise and efficient in delivering space comfort. Often referred to as variable tonnage systems, they have the capability to match space loads at any condition while adjusting the power consumed accordingly. In the next section, we will discuss several components of the system that enable this load adaptability mechanism and high-efficiency pattern.

Multi-Zone VAV System Components

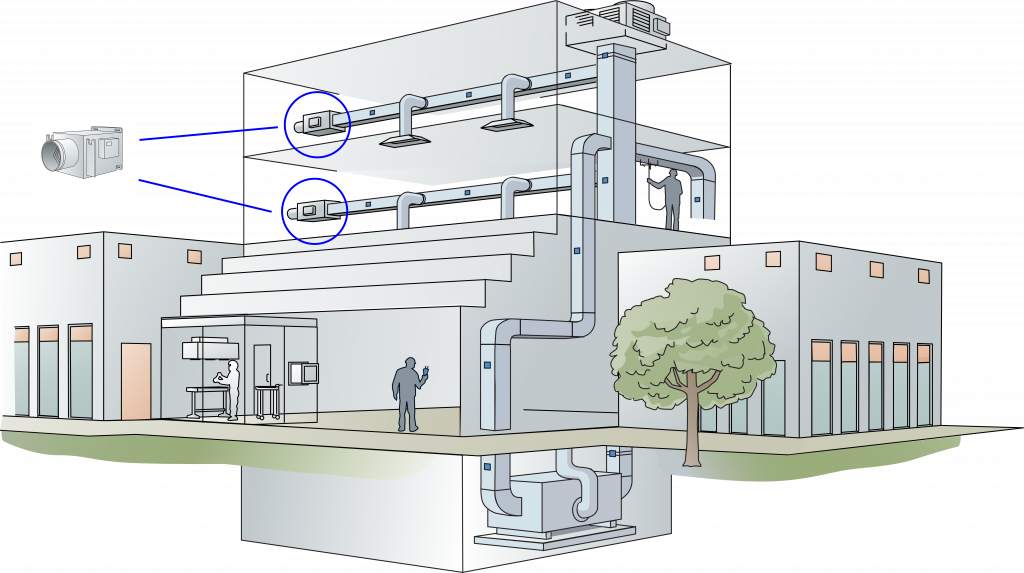

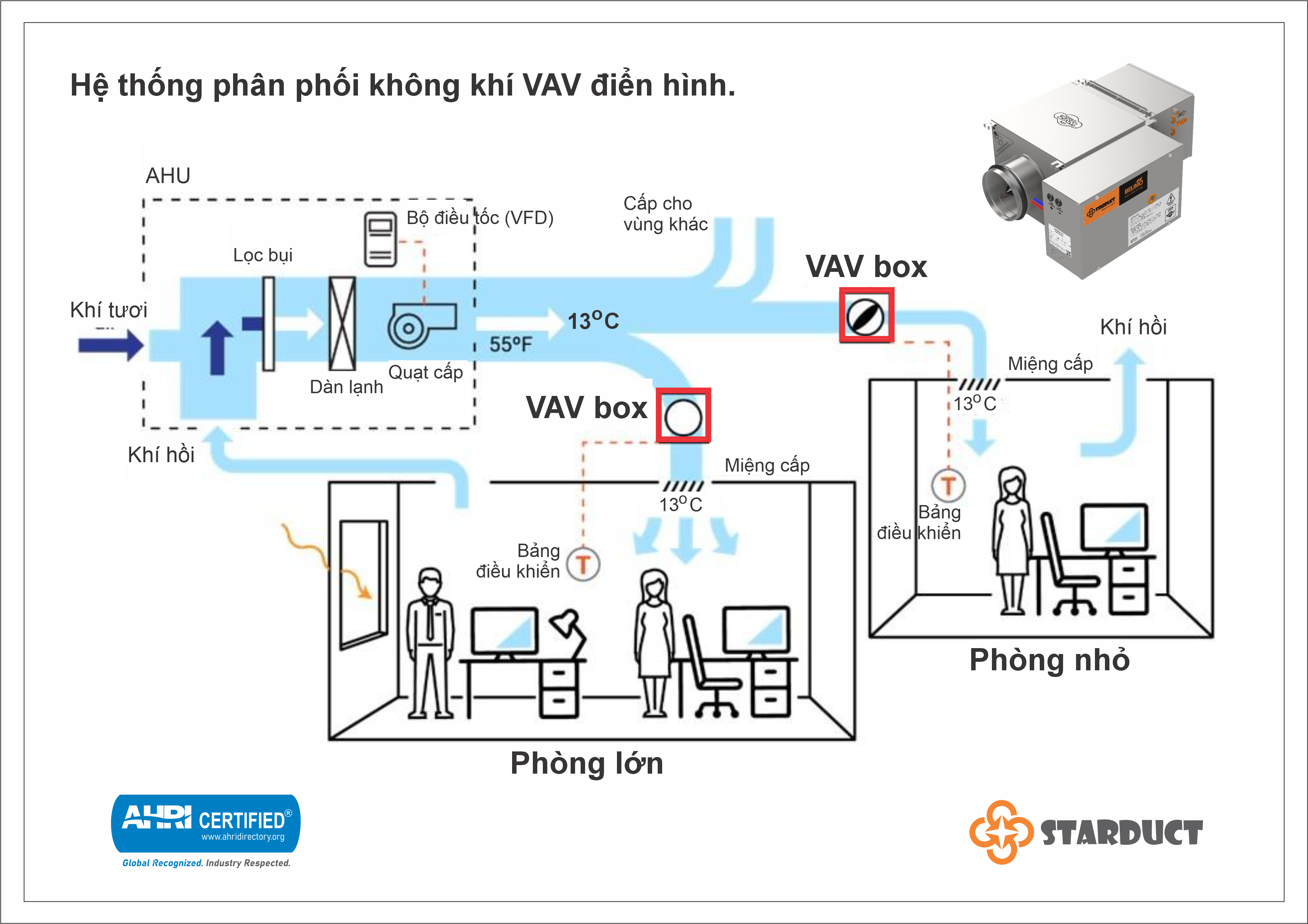

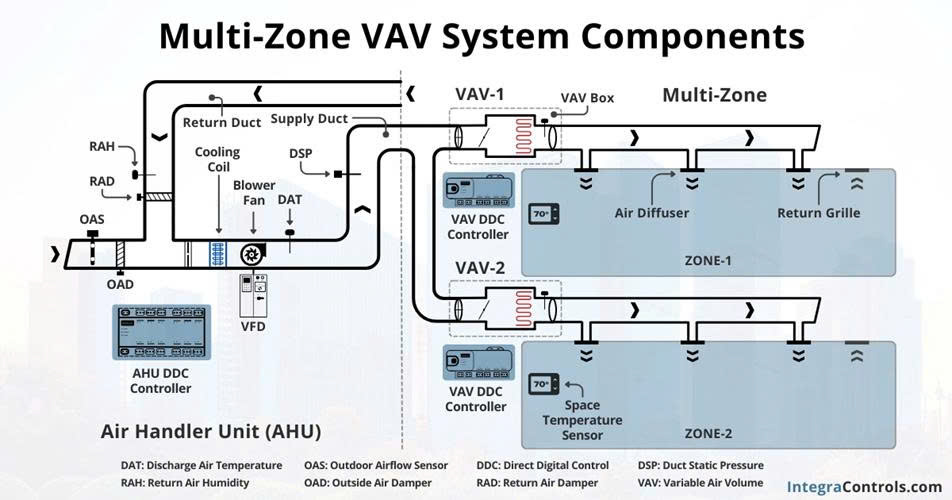

In multi-zone applications, a typical VAV system consists of several mechanical components, including an air handling unit (AHU) with a cooling coil (compressor or chilled water), a blower fan, and an inverter-duty motor driven by a variable frequency drive (VFD). The VFD is the component responsible for enabling the variable airflow characteristic of the system.

Air is distributed through supply and return ducts, although plenum air return applications are also common. Motorized dampers for outside air and return air are utilized to control unit ventilation.

The entire zone served by the main AHU is divided into different thermal zones, each having a dedicated box or terminal unit per zone. These boxes, known as variable air volume boxes or VAV boxes, typically incorporate a reheating device such as an electric heater or a hydronic coil served by a boiler. The main components of a VAV box will be discussed in more detail in the next section of this article. Finally, air is delivered into the space through air diffusers.

System control is primarily provided through direct digital control (DDC). Both the AHU and the VAV boxes are equipped with DDC controllers that communicate with each other via a building automation system (BAS) network. System supervision is often carried out through a building management system (BMS), enabling operators to adjust setpoints, monitor system performance, and be aware of possible system faults.

Multi-Zone VAV System: VAV Box

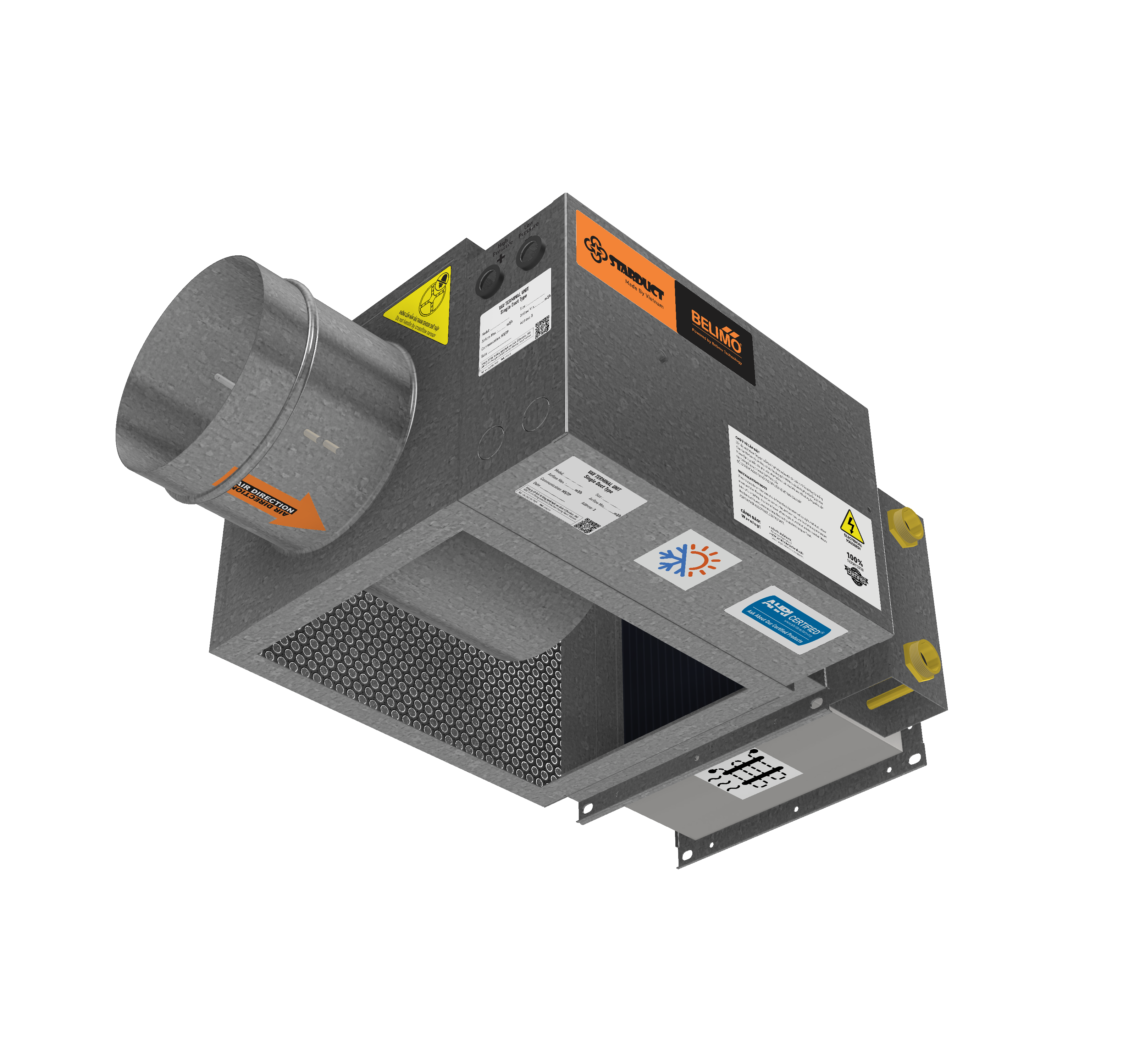

A variable air volume box (VAV Box) serves as a terminal device in a multi-zone VAV system, responsible for controlling the temperature in the respective zone.

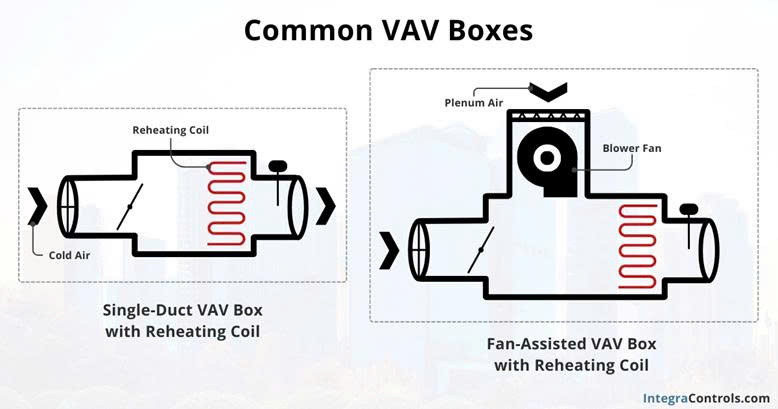

Various types of VAV boxes exist, categorized based on the components they incorporate and their mechanical configuration:

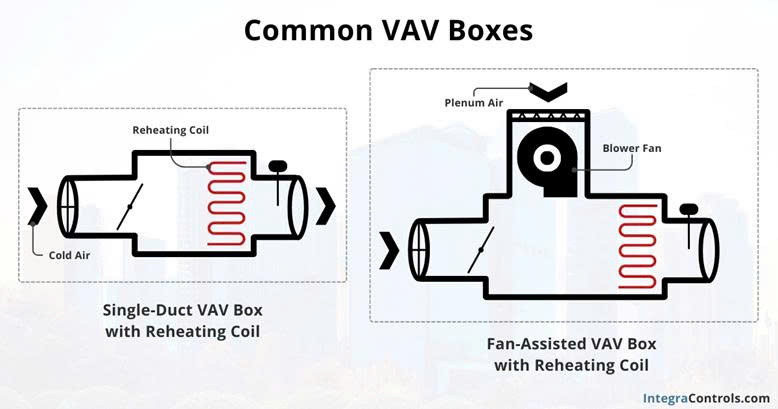

- Single-duct VAV box: This is the most common type, configurable as cooling-only or with reheating.

- Fan-assisted VAV box: A booster fan is used to draw warmer plenum air/return air into the zone and displace the required reheat energy.

- Dual-ducted VAV box: The main system has a separate duct for warm (or neutral) and cold air, with modulated flow to deliver air as needed.

- Induction VAV box: Instead of a fan, it employs the induction principle to draw warmer plenum air/return air into the zone and displace the required reheat energy.

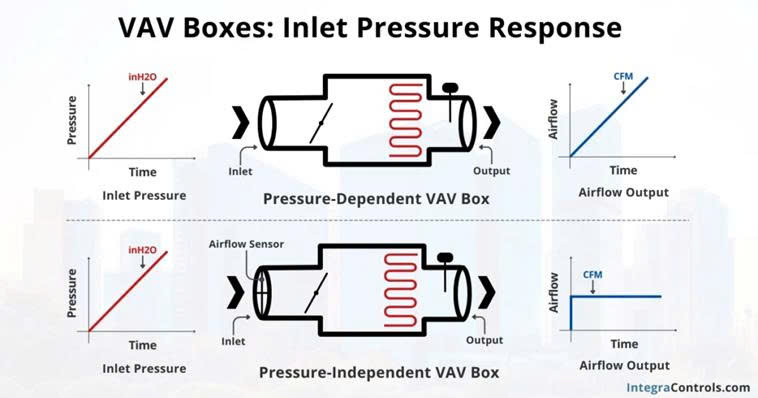

The selection of a VAV box type depends on the design criteria and the specific application characteristics. Beyond these types, there’s a broader classification based on their airflow output characteristic relative to variations in inlet pressures:

- Pressure-dependent VAV box: Used in variable air volume and temperature (VVT) applications. Airflow varies according to pressure variations in the VAV box inlet.

- Pressure-independent VAV box: Employed in multi-zone VAV systems. Airflow is independent of pressure variations in the VAV box inlet and typically includes an airflow measuring device.

In the remainder of this article, we will focus on pressure-independent single-duct VAV boxes with reheating coils, commonly observed in multi-zone VAV applications.

Bình luận (0)