Introduction to VAV Box and VAV System

Author: Starduct Academy Team Published: 2025

This document provides only the basic concepts and scope—serving as definitions—for topics related to VAV Box products and VAV systems. It is intended as an introduction and a guide for further study by sales engineers and MEP engineers who are beginning to explore VAV technology.

Table of Contents

- Introduction to VAV Box

- Comparison: VAV System vs. VRV System

- Steps to Begin Designing a VAV System

- Classification and Applications of VAV Boxes

- Technical Specifications and Design Standards

- Ductwork Design for VAV Systems

- Airflow, Pressure Calculations, and VAV Selection

- Integration with Other Systems

- Installation, Testing, and Commissioning

- DDC Device Selection and System Control

- Maintenance of VAV Systems

- AI, IoT, and Smart Building Applications

- Comparison with Other HVAC Solutions

- Case Study – Real-World VAV System Design

- Summary of Investment Efficiency

1. Introduction to VAV Box

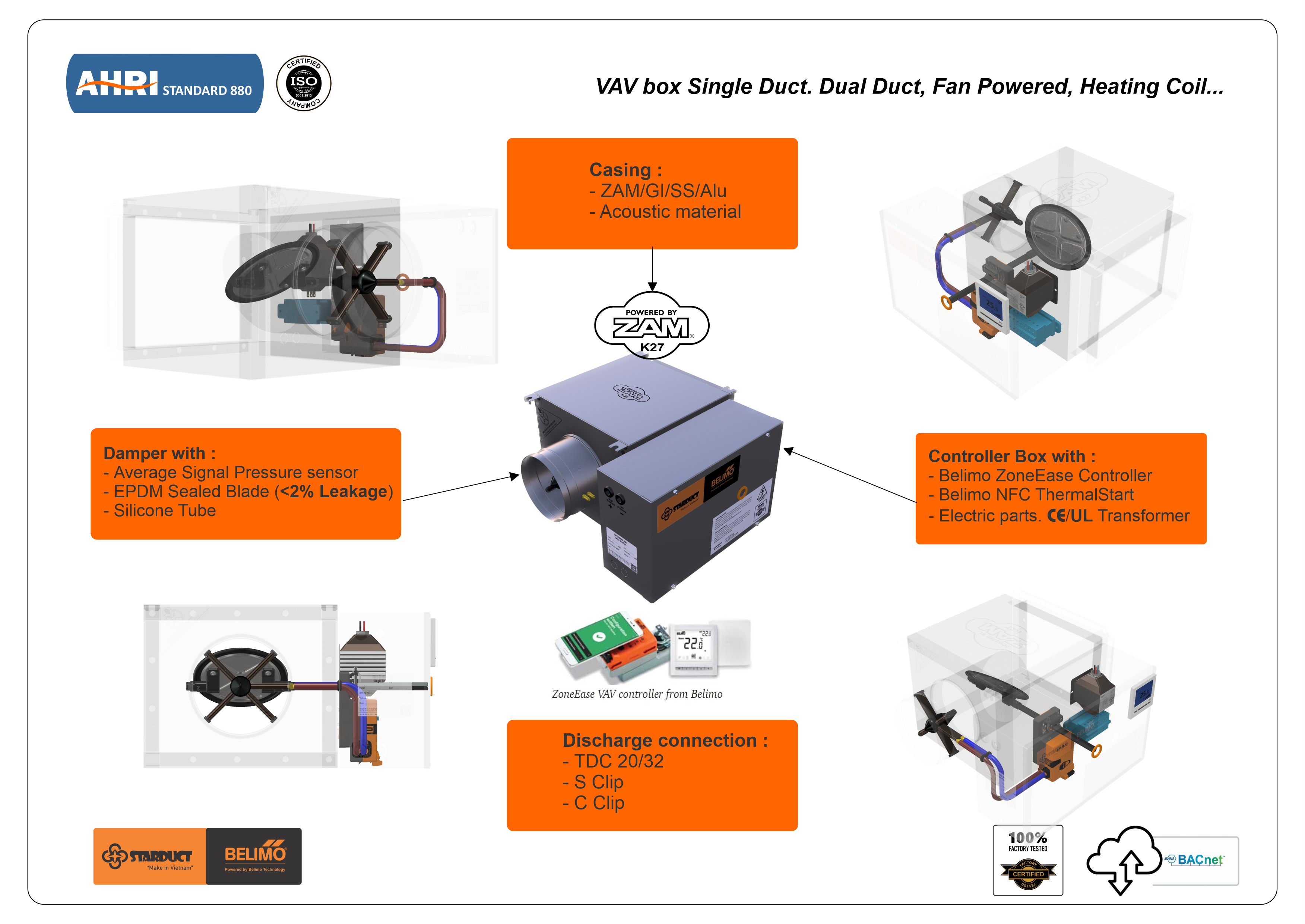

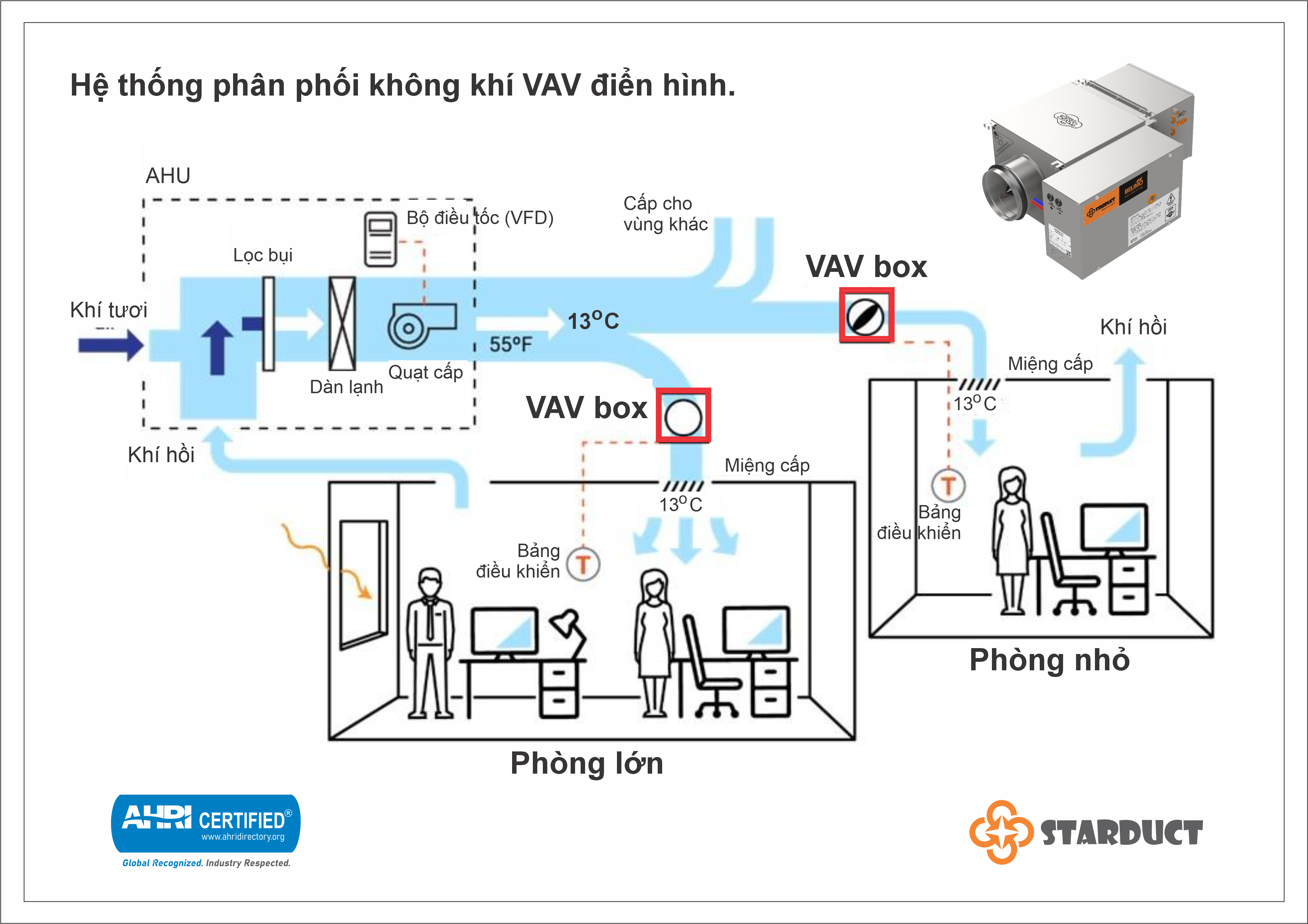

A VAV (Variable Air Volume) Box is a key component in central HVAC systems. It adjusts the supply airflow to each space based on actual demand. Common types include:

- Single Duct

- Dual Duct

- Fan Powered

- Reheat

- VAV Diffuser

VAV systems optimize energy use, ensure thermal comfort, and maintain indoor air quality.

2. VAV vs. VRV Systems

- VAV System: Uses a central AHU and VAV Boxes to regulate airflow. Ideal for large-scale projects with lower investment and energy costs.

- VRV System: Suitable for small to medium buildings. Higher investment but easier to operate.

| Criteria | VAV System | VRV System |

|---|---|---|

| Initial Cost | Lower | Higher |

| Electricity Cost | Lower (efficient AHU) | Higher |

| Maintenance | Lower (simpler structure) | Higher |

AHU Heat Sources:

- Chiller (Water/Air Cooled)

- Heat Pump

- Boiler

- DX Coil

Choose the appropriate heat source based on project type.

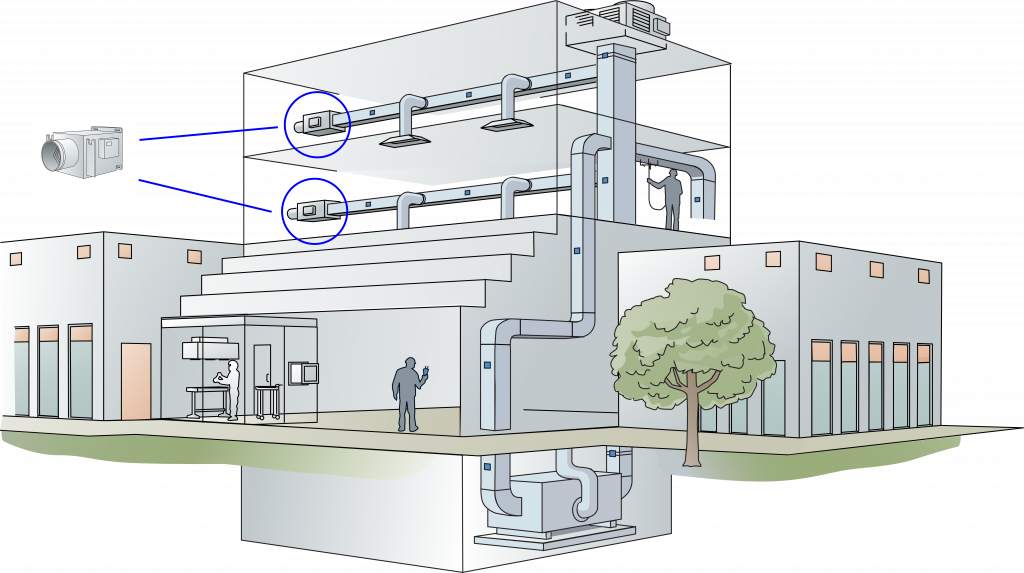

3. Steps to Design a VAV System

- Survey thermal loads and zone layout

- Define main AHU and number of VAV Boxes

- Create schematic diagrams and select VAV types

- Calculate airflow and pressure loss

- Choose controllers and sensors

Advanced topics include sensor selection, BMS integration, and energy simulation.

4. VAV Box Types and Applications

- Single Duct VAV: Common in offices and meeting rooms

- Fan Powered VAV: Includes fan for stable airflow

- Reheat VAV: Includes electric/hot water coil for precise temperature control

- VAV Diffuser: Ceiling-mounted, adjusts airflow at outlet

Safety for Reheat VAV:

- Overheat protection: temperature limit sensor

- No-airflow protection: airflow sensor to shut off heater

5. Technical Specs and Standards

- Complies with AHRI 880, ASHRAE 62.1, 90.1

- Sound-insulated materials, galvanized or aluminum casing

- Strict control of noise and pressure loss

6. Ductwork Design for VAV

- Calculate airflow per zone

- Select duct size to minimize pressure loss

- Optimize layout for balanced air distribution

7. Airflow, Pressure, and VAV Selection

- Airflow (CFM) = thermal load / ΔT

- Calculate pressure to select suitable AHU

- Use software like HAP or Trace 700 for accurate design

8. Integration with Other Systems

- BMS, CO₂, temperature, humidity sensors

- AHU, chillers, heat exchangers

- Coordinated operation ensures energy savings and IAQ

9. Installation, Testing, and Commissioning

- Install per drawings, verify sensor connections

- Calibrate Vmin/Vmax for each box

- Test operation with AHU

10. DDC Device Selection and Control

- Brands: Belimo, Siemens, Johnson

- Multi-level control: zone → floor → central

- Redundancy: dual power supply, dual network

11. Maintenance

- Clean sensors, check actuators

- Verify BMS connections

- Plan regular inspections

12. AI, IoT, and Smart Building Integration

- AI learns user behavior

- IoT enables remote cloud connectivity

- Integrates with smart management platforms

13. Comparison with Other HVAC Solutions

| Criteria | VAV | VRV | FCU |

|---|---|---|---|

| Investment | Medium | High | Low |

| Electricity | Low | Medium | High |

| Maintenance | Low | High | Medium |

| IAQ Efficiency | High | Medium | Low |

| Lifespan | 15–20 yrs | 10–15 yrs | 7–10 yrs |

14. Case Study – Real-World VAV System

- Project: 5-story office, 1,000 m²/floor

- Design: 1 AHU (80,000 CMH) + 40 VAV Boxes

- Results:

- 30% lower investment than VRV

- 20% lower operating cost

15. Investment Efficiency Summary

| Criteria | VAV | VRV |

|---|---|---|

| Investment | 4.2 billion VND | 6.5 billion VND |

| Electricity | 300 million/year | 360 million/year |

| Maintenance | 100 million/year | 200 million/year |

| Payback Period | 4.1 years | 8.5 years |

Conclusion:

VAV systems offer long-term cost advantages, durability, and superior air quality control for large buildings.

Bình luận (0)